Enabling Next Generation Hybridized Wood Buildings for Sustainable Construction

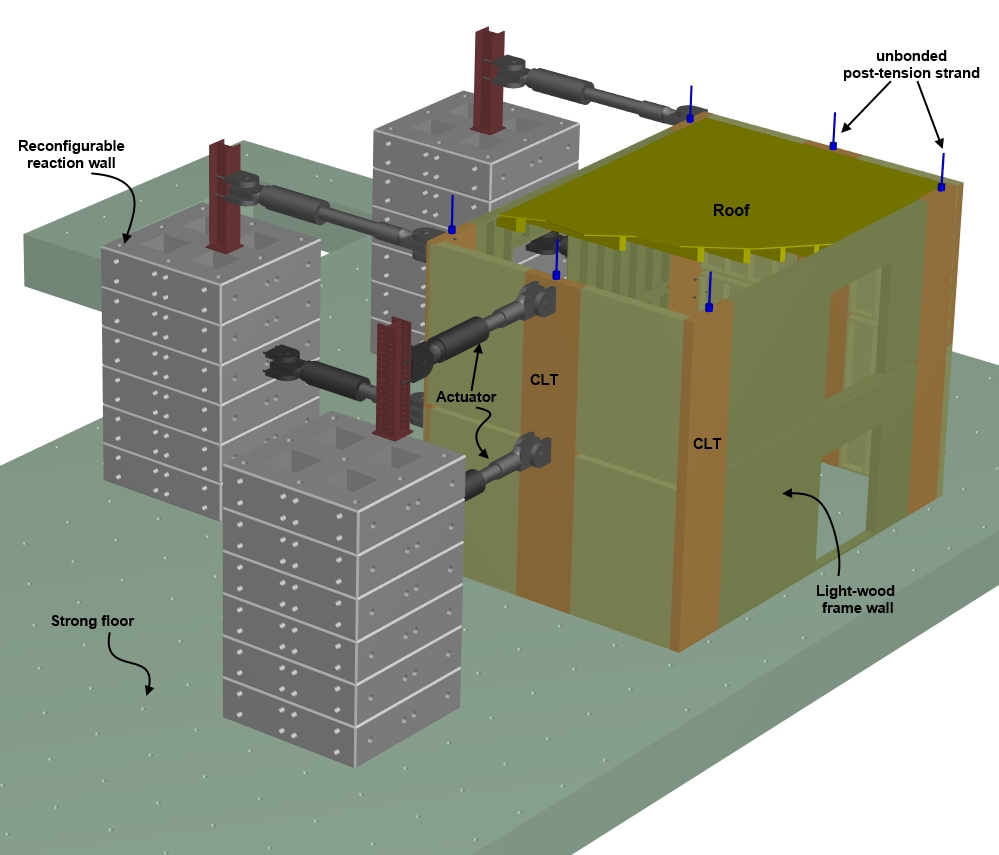

Current, Supported by National Science FoundationIn this project, the seismic behavior and optimization of a hybridized self-centering wood system termed a CLT-LiFS that uses unbonded post-tensioning tendons, cross-laminated timber (CLT) rocking walls and light-frame wood systems (LiFS) will be investigated to enable the design of tall wood buildings that are sustainable and resilient. In this system, the CLT panel anchored with unbonded post-tensioning will be optimally combined with the light-wood frame system to exploit the beneficial features of each. While the unbonded post-tensioning in the CLT will self-center the system, the connections in the light-frame wood will provide the necessary energy dissipation. Preliminary studies on CLT-LiFS have shown their excellent seismic performance with minimal structural damage, but key research challenges focused on their compatibility remain. In order to make this system a reality, optimal configurations of CLT-LiFS systems, performance of connection details between the CLT and the light-frame wood and long-term behavior of CLT load under sustained loading needs to be better understood. The fundamental contributions of this project are: 1) Experimentally validated analytical models for the creep behavior of CLT under different environmental conditions, and its inclusion into analytical models for tall wood buildings, 2) the use of reliability concepts for performance assessment of the hybrid system. 3) Experimentally quantifying the secondary systems impact on the behavior of tall buildings with CLT-LiFS systems, and 4) development of connections between the CLT-LiFS system and secondary systems. The intellectual merit of this project is the development of a fundamental understanding of how the hybridized system behaves compared to each of the individual systems thereby serving as the foundation to develop the design methodology and procedures to meet pre-specified resiliency and sustainability building requirements for this new building type. The broader impacts are that this work will facilitate a new generation of improved performance-based building systems to achieve resiliency and sustainability goals. All anticipated project outcomes will ultimately produce new basic knowledge needed to design safer, more resilient wood buildings in seismic regions and thus contribute to seismic hazard mitigation in the United States and around the world.

Light-gauge cold-formed steel (CFS) is being used more and more as an economical yet high performing

construction material. This project examines the performance of an innovative light-gauge cold-formed

steel system called the uniform truss construction system (UTCS), which includes floor trusses,

open panels, V-braced panels, columns, and connections between components. The performance of the

system to earthquake and wind load is investigated separately. The floor trusses carry dead load and

live load from the floor and transfer these loads to open panels and V-braced panels. The open

panels and V-braced panels transfer the load from floor trusses to columns. A series of

reversed-cyclic tests of sub-assembly structures (V-braced panels) were conducted to provide the

key information needed to numerically model the performance of the system under cyclic loading.

The test data was then integrated into a numerical model for non-linear time history analysis.

Non-linear time history analysis of the UTCS subjected to earthquake ground motion was conducted using

a suite of 22 prominent earthquakes recorded from around the world. The results show that the UTCS

performs very well compared with the ASCE Standard 41 required performance criteria at the system

level. The system was shown to also perform very well when subjected to wind loads in excess of

the ASCE7-10 (2010) wind loads. Based on the testing and analysis, it was concluded by

the research team that the UTCS developed by Prescient is a viable system all regions including

high wind and high seismic areas. Additional research is suggested to develop an R-factor

per FEMA P-695.

The UTCS is a product of The Prescient Companies, LLC and patents are pending on the system.

The information, specimens, and funding for this study was provided by The Prescient Companies, LLC,

and that support is gratefully acknowledged. Detailed assistance was provided by Michael Lastowski

and John Vanker of TPC.